The following article was submitted to us/written by John Schumann

As an Aviation Quality Assurance Manager I have inspected multiple fleets of King Air 350’s with varying approaches to conformity with the B300/B300C HUIP, specifically regarding scheduling. Some fleet managers remove the aircraft from service for the entirety of a Detail or Routine Inspection while other fleet managers perform a section of the inspection at various times within the tolerance window while allowing the aircraft to return to service between tasks. Inspections performed in this manner are referred to as “piecemeal” or “running” inspections.

In October of 2013 King Air Series Model Communiquè 2013-04 was released which provided an initial overview of the HUIP program. However, this Communiquè is outdated for the B300/B300C King Air community in that it only addressed tolerance windows that at the time were +10 flight-hours. The current tolerance window of ±20 flight-hours adds a bit more complexity and confusion that I hope to clarify here.

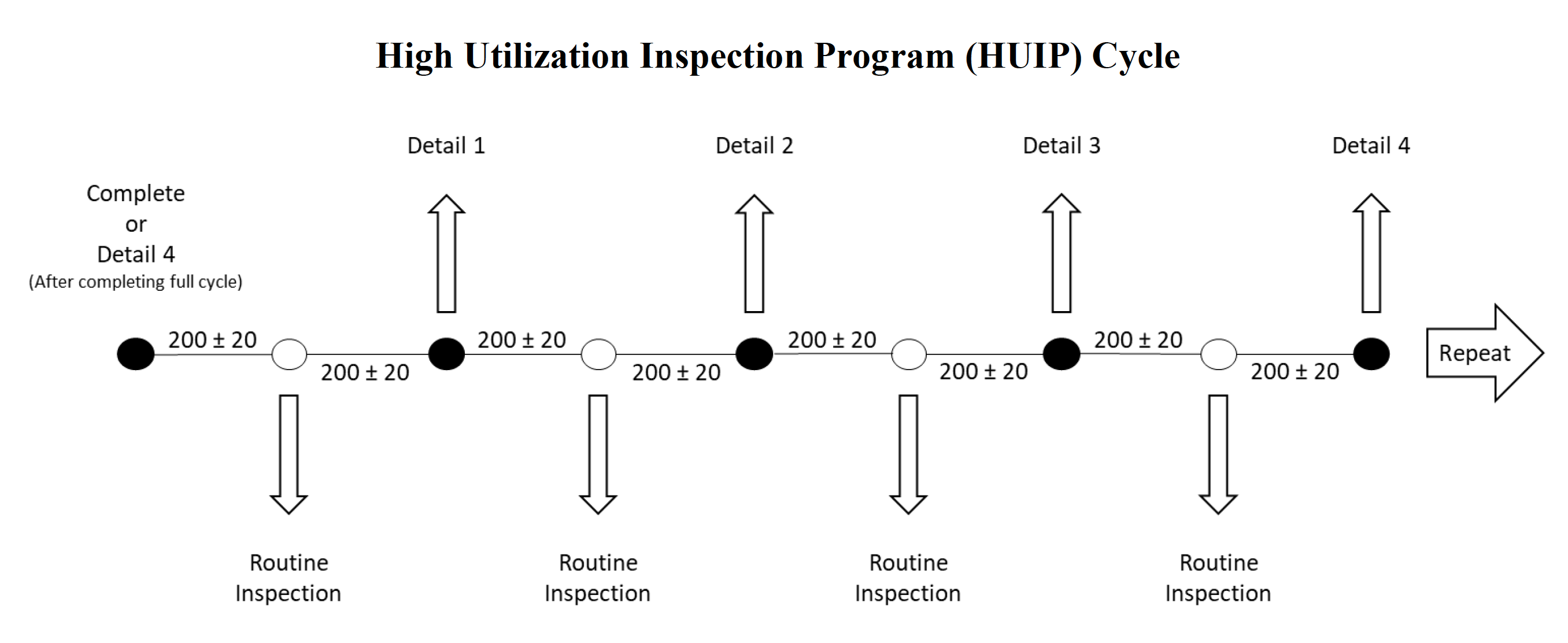

HUIP Cycle

The complete HUIP cycle consists of eight inspections, four Detail Inspections, and four Routine Inspections. Figure 1 illustrates the complete HUIP cycle.

Inspection Intervals

Detail Inspections – 400 Hours.

Routine Inspections – 200 Hours between each Detail Inspection.

Inspection Interval Tolerance

Detailed/Routine Inspections (Flight Hour Interval) – A tolerance of ± 20 flight-hours is allowed per Inspection.

• 200 ± 20 flight-hours is the maximum allowed between any inspections.

• Tolerances do not accumulate.

– Therefore any tolerance used early, (-) tolerance, must be subtracted from the next (+) tolerance window.

– In other words, all of the (-) tolerance window cannot be utilized one inspection, and then all of the (+) tolerance window the following inspection and remain within compliance of the HUIP.

• Once baselined, inspection “due at” times will not change during the entire HUIP cycle unless:

– The operator has an inspection performed early and outside the tolerance window; or

• Requires remaining due at times to be re-baselined.

– The operator allows an aircraft to fly beyond a tolerance window, or exceed 220 flight-hours between inspections.

- Any exceedances used beyond the inspection tolerance must be subtracted when calculating the next repetitive inspection(s).

- In other words, the due at times for the remaining inspection (s) would slide to the left by the number of hours the inspection was overflown.

“Piecemeal” or “Running” Inspections are not allowed.

Tolerance windows are not intended to allow the maintainer to prematurely approve an aircraft for return to service before fully completing the inspection. The term inspection refers to the applicable Detail or Routine Inspection and not a task described as an “inspection” within.

It is intended that the operator remove the aircraft from service before maintenance begins any task defined within the applicable Detail or Routine Inspection, and the maintainer shall not approve the aircraft for return to service until the entire Detail/Routine Inspection is complete.

Calculating Next Due/Due At and Utilizing Tolerance Windows

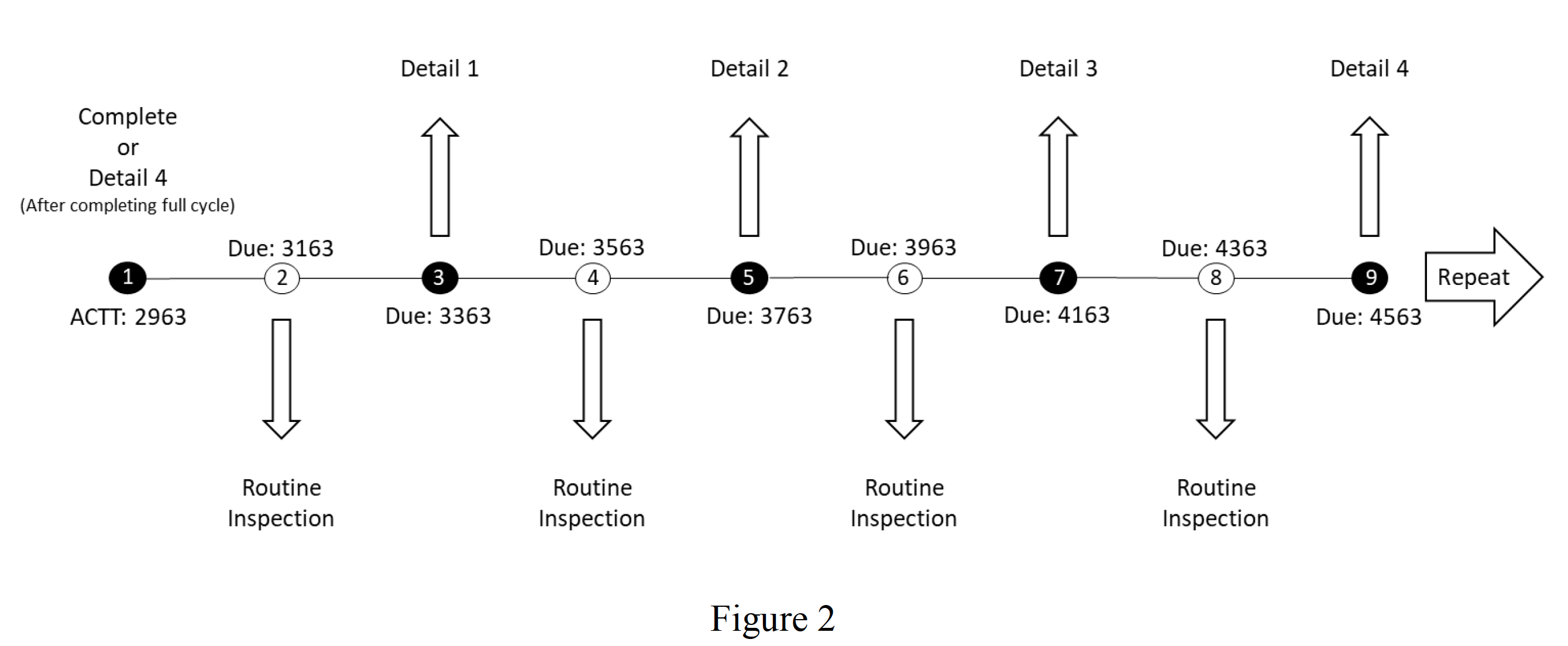

Examples illustrating how to calculate Next Due and utilize tolerance windows are defined below and based on the following example of aircraft total time (ACTT) information. The numbers within parentheses, i.e. (1), correlates with numbers on the timeline within the figures:

(1) Complete 1-4 performed at ACTT: 2963 aircraft enrolled in HUIP.

This complete 1-4 Inspection is the baseline for calculating the continuing “due at” times for the remaining inspections in the cycle as follows:

A. Routine Inspection (2) due at ACTT: 3163, w/a tolerance window of ± 20

B. Detail 1 Inspection (3) due at ACTT: 3363

C. Routine Inspection (4) due at ACTT: 3563

D. Detail 2 Inspection (5) due at ACTT: 3763

E. Routine Inspection (6) due at ACTT: 3963

F. Detail 3 Inspection (7) due at ACTT: 4163

G. Routine Inspection (8) due at ACTT: 4363

H. Detail 4 Inspection (9) due at ACTT: 4563

Example #1

As stated above, the next Routine Inspection (2) is due at ACTT: 3163, with a tolerance window of ± 20 flight-hours. Assume the operator has the Routine Inspection (2) completed as soon as the aircraft comes into the tolerance window at ACTT: 3143.

Performing the Inspection at this time does not affect any due at times for the remaining inspections within the cycle.

However, it does affect the tolerance window for the next Inspection. Keep in mind that tolerances do not accumulate, and the maximum allowable time between inspections is 220 hours.

Therefore the 20 flight-hour tolerance utilized in this window must be subtracted from the next Inspection. Detail 2 Inspection (3) is still due at ACTT: 3363, but now the tolerance window is only -20. In other words, the program must complete the Inspection between ACTT: 3343 and ACTT: 3363. If the aircraft is allowed to fly beyond ACTT: 3363, the maximum allowable time between inspections of 220 flight-hours will be exceeded (3143 + 220 = 3363).

Example #2

Continuing with the above example, assume the operator has the Detail 1 Inspection (3) completed at ACTT: 3353. In the above example, the tolerance window for this Inspection was defined as -20 flight- hours. Remember, the operator utilized the + 20 flight-hours in the previous tolerance window, and tolerances do not accumulate. The operator had the Inspection completed within the tolerance window. Therefore, there is not an effect on any due at times for the remaining inspections within the cycle. The times identified in Figure 2 are still true.

However, it does again affect the tolerance window for the next Inspection. Keep in mind that tolerances do not accumulate, and the maximum allowable time between inspections is 220 hours.

The next Routine Inspection (4) will still be due at ACTT: 3563, but now the tolerance window is -20 / +10. The operator must have the next Routine Inspection (4) completed between ACTT: 3543 and ACTT: 3573. Again, if the operator does not adjust the tolerance window from ±20 to -20 / +10 and the aircraft is flown to ACTT: 3583, utilizing +20, the aircraft would have operated more than 220 flight-hours between inspections and the aircraft would be out of compliance.

Example #3

Continuing with the information provided in Example #2, assume that the operator had the next Routine Inspection (4) completed at ACTT: 3568. The operator utilized +5 of the allowable +10 flight-hours in the tolerance window. Again, there is not an effect on the remaining due at times within the cycle. The next Inspection, Detail 2 Inspection (5), is due at ACTT: 3763, with a tolerance window of ±20 flight-hours.

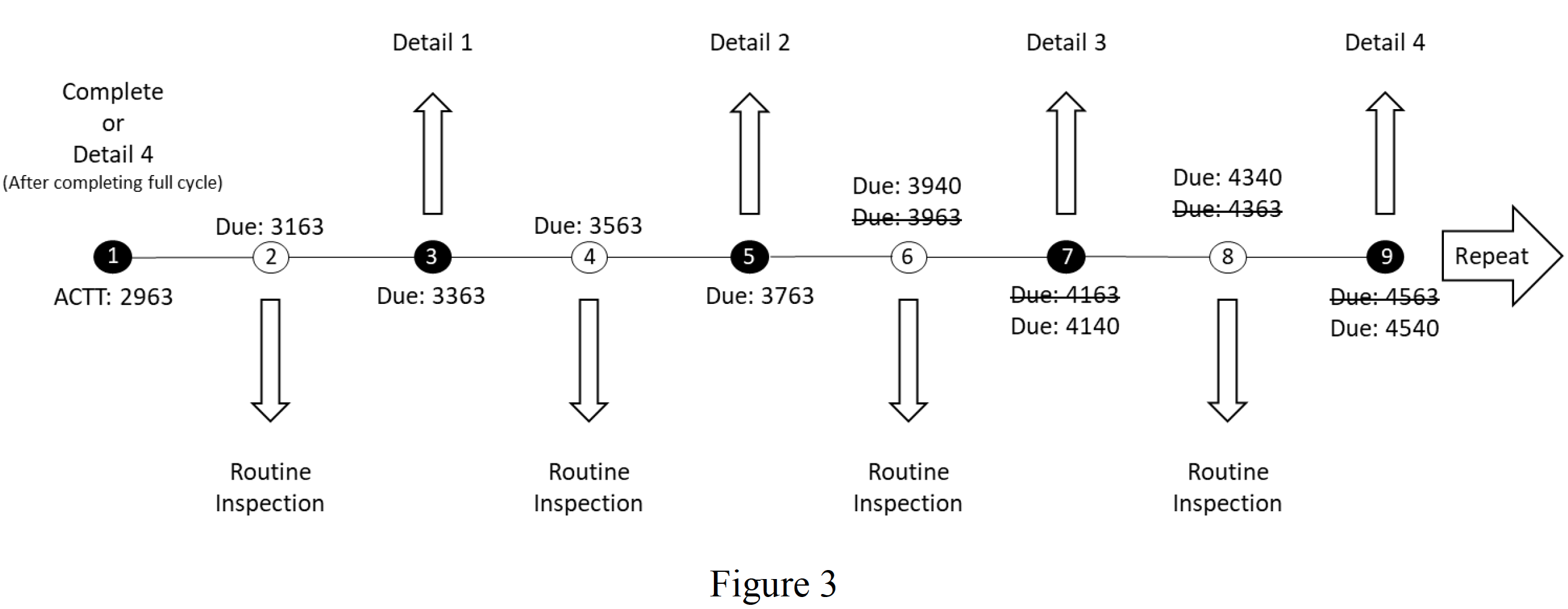

Example #4

Considering the Detail 2 Inspection (5) due at and tolerance window defined within example #3, assume the operator has the Detail 2 Inspection (5) completed at ACTT: 3740. The program has completed this Inspection early and outside the tolerance window. Therefore, there is an effect on the remaining due at times for the remainder of the cycle. The remaining due at times for the cycle must be re-calculated as outlined below in Figure 3:

A. (6) Routine Inspection due at ACTT: 3940, with a tolerance window of ± 20

B. (7) Detail 3 inspection due at ACTT: 4140

C. (8) Routine Inspection due at ACTT: 4340

D. (9) Detail 4 inspection due at ACTT: 4540

Performing the inspection early and outside the tolerance window, 23 flight-hours before the due at time, caused the remaining inspections to slide to the left by 23 flight-hours.

Example #5

Continuing the same scenario, assume the operator had the next Routine Inspection (6) completed at ACTT: 3960. The inspection was due at ACTT: 3940, with a tolerance window of ±20 flight-hours. Since the operator had this inspection completed within the positive side of the tolerance window, there is not an effect on the remaining due at times within the cycle, nor will there be a need to adjust the next tolerance window. Detail 3 Inspection (7) will remain due at ACTT: 4140, with a tolerance window of ±20 flight-hours. The program has flown the aircraft the maximum allowable time between inspections, 220 flight-hours (3960 – 3740 = 220), and allowed for the program to fly the aircraft the minimum number of flight-hours if the program performs the next inspection at the earliest opportunity within the following tolerance window.

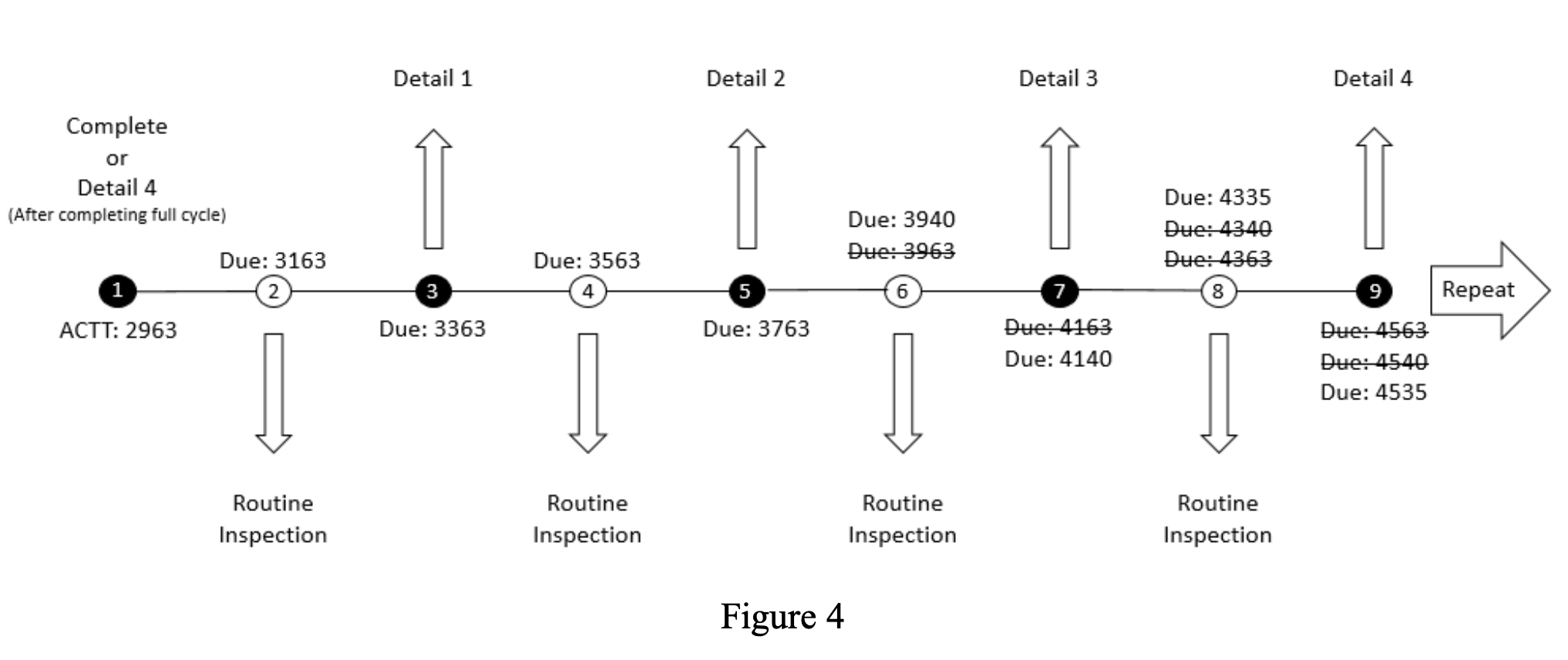

Example #6

This final example will continue with the same scenario and assume the operator was not able to have the Detail 3 Inspection completed before ACTT: 4160. Instead, the operator had the Detail 3 Inspection completed at ACTT: 4165. Since the operator flew the aircraft 5 flight-hours beyond the tolerance window, the 5 flight-hours must be subtracted from the remaining due at times within the current HUIP cycle. The remaining due at times for the cycle must be re-calculated as outlined below in Figure 4:

John Schumann

Aviation Quality Assurance Manager