*Service bulletin from Pratt & Whitney now below.*

**Edited to Add the Service Bulletin from Pratt & Whitney**

The aviation industry experienced a critical safety decision on February 16, 2024, when the Federal Aviation Administration (FAA) issued an emergency Airworthiness Directive (AD) affecting many aircrafts powered by Pratt & Whitney engines.

The engines affected by this issue:

- PT6A-64, PT6A-66, PT6A-66A, PT6A-66B, PT6A-66D, PT6A-66T, PT6A-67, PT6A-67A, PT6A-67AF, PT6A-67AG, PT6A-67B, PT6A-67D, PT6A-67F, PT6A-67P, PT6A-67R, PT6A-67RM, PT6A-67T, PT6A-68, PT6A-68B, PT6A-68C, PT6A-68D, PT6A-68T, PT6E-67XP, and PT6E-66XT.

The aircrafts that could be affected by this issue:

- King Air 350/300 Fleet

- King Air 1900

- PC 12

- TBM

- Caravan

- Piaggio

- Evolution

- Starship

- Epic

- amongst others

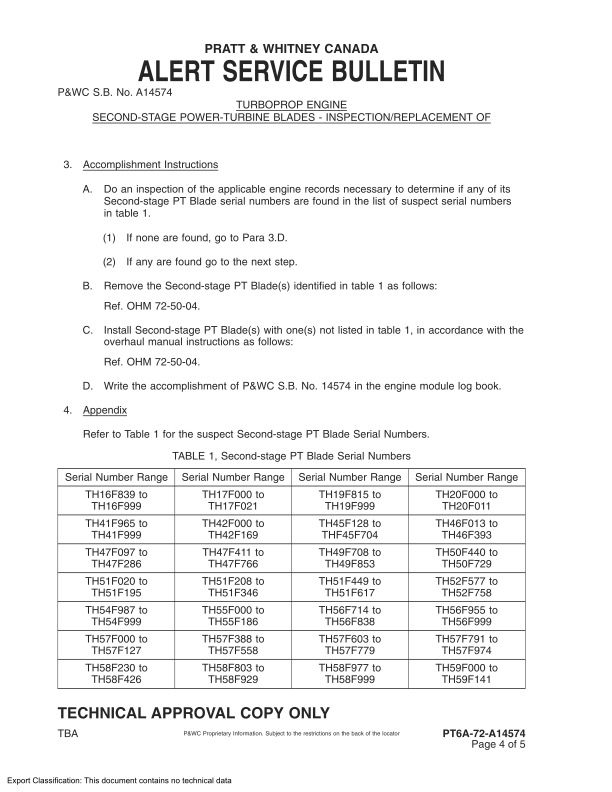

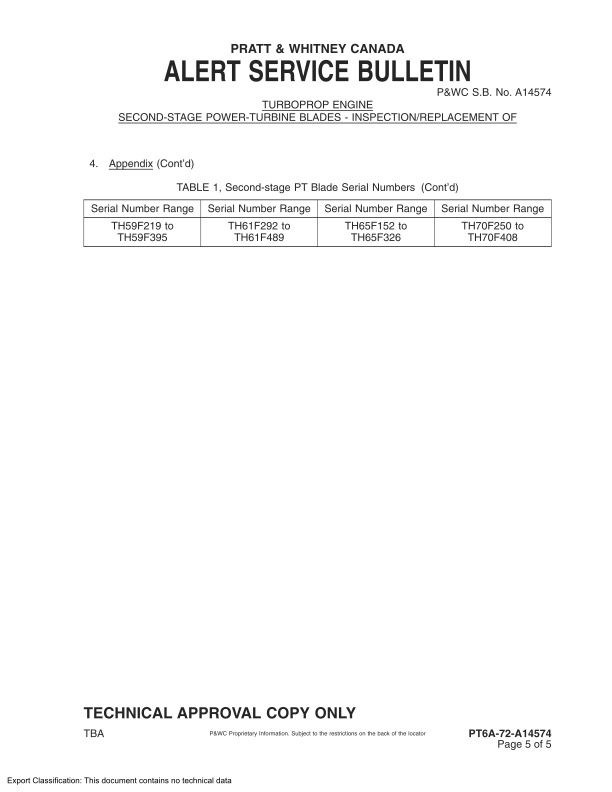

Affected blade serial numbers are listed in a table in the AD and also “have accumulated less than 50 hours air time since new, or since shop visit, or since second-stage power turbine repair.” These blades must be removed and not used.

According to the company, “[P&WC] has recently identified a limited subpopulation of high power PT6A and PT6E engines that require part replacement before returning to service. The population is limited to engine parts with less than 50 flight hours (total, or since last shop visit, or total time since second stage power turbine repair) manufactured from a single batch of sourced product. [P&WC] is working with airframers, operators, and Transport Canada to issue fleet instructions and to schedule maintenance.” The company pointed out that the issue with the PT2 blades “is not powder-metal-related.”

Replacement of the affected blades should take, P&WC said, “from one to four weeks. Single aircraft operators with limited access to an overhaul facility will take closer to four weeks, while those with access to shops can turn an engine in less than a week.”

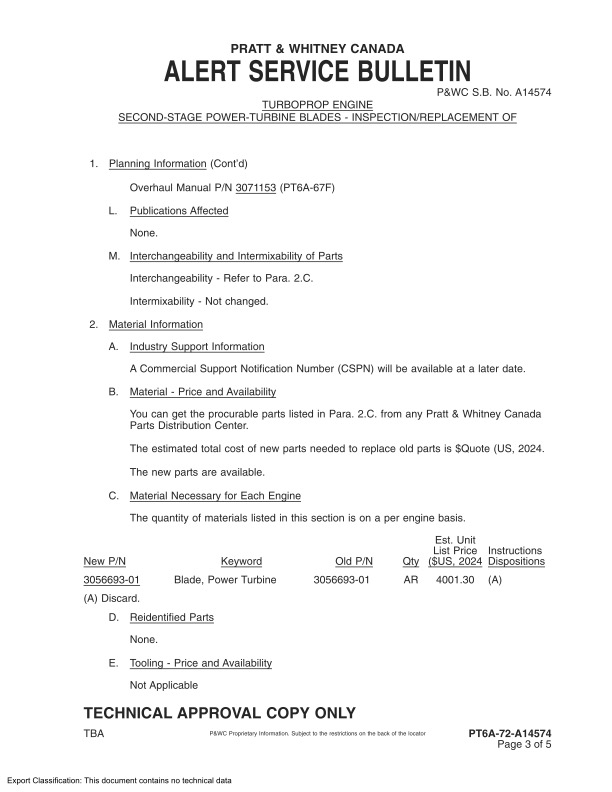

About 5,000 blades made from the suspect raw material are affected. “Each PT6 engine has 43 blades on the second turbine disk, but each engine may have a blade population sourced from various raw material (co-mingled inventory).”

The Issue: Blade Failures

This emergency AD was prompted by reports of second-stage power turbine (PT2) blade failures in Pratt & Whitney engines.

These particular PT2 blades with part number 3056693-01 were relatively new in the market, sourced from the same batch of raw material and showing propensity to fail with less than 25 hours of airtime.

The implications of these failures are severe, with risks ranging from engine power loss to an in-flight shutdown leading to emergency landings or compromised aircraft control. It presents a clear and present danger to the safety and reliability of the aircraft operations.

The Interim Solution

The FAA implemented preventative measures through this emergency AD to forestall further occurrences of PT2 blade failures after identifying the risk as potentially widespread across the fleet. The AD mandates the removal of the affected PT2 blades before any additional flight operations.

The Investigation Continues

While this emergency AD serves to mitigate immediate risks, investigations into the root cause are ongoing. Pratt & Whitney's in-depth examination of the failures is expected to yield answers that will guide long-term solutions and possibly influence future rulemaking or airworthiness directives.

Moving Forward

As the aviation industry continues to evolve and face new challenges, the lessons learned from this instance will undoubtedly shape future safety protocols and procedures. It is a reminder of the ever-changing landscape of aviation and the importance of remaining proactive in ensuring safe and secure operations for all involved. With swift, coordinated action, the aviation community can continue to prioritize safety while also pushing boundaries and advancing technology

The topic has been heavily commented on social media.

"Word of advice, if you evaluate your data and determine the AD is non-applicable, record that in your logbook. This has been issued as 'before next flight' which essentially grounds all the aircraft engines affected. Log entry of non-applicability shows you complied." — Robert Craymer, Covington Aircraft, a Pratt & Whitney-approved overhaul facility

________

The full AD can be found below. Link to AD on the FAA website at the bottom of this article.

________

Service bulletin from Pratt & Whitney can be found below.

**Edited to Add the Service Bulletin from Pratt & Whitney**

See FAA report here: https://drs.faa.gov...

Image: Blackhawk Aerospace