September 8, 2025

Flying your King Air into remote destinations comes with its own set of rewards — breathtaking scenery, unique destinations, and a sense of adventure. But it also carries unique risks, and one of the most overlooked is fuel contamination.

When operating in areas where fuel storage, transportation, and filtration may not meet the same standards you’re used to, the risk of water, particulate, or microbial contamination increases. And for a King Air, even a small amount of contaminated fuel can cause big trouble.

Why Fuel Contamination Happens in Remote Locations

-

Aging or Improperly Maintained Storage Tanks – Rust, sediment, and water can accumulate in poorly maintained fuel farms.

-

Transportation & Transfer Risks – Fuel truck hoses, nozzles, or filters may be worn or compromised.

-

Environmental Factors – Humidity, rain, or extreme temperature swings can cause condensation inside tanks or containers.

-

Low Turnover of Fuel – If a location doesn’t see much air traffic, stored fuel can degrade over time.

Signs You Might Have a Fuel Issue

-

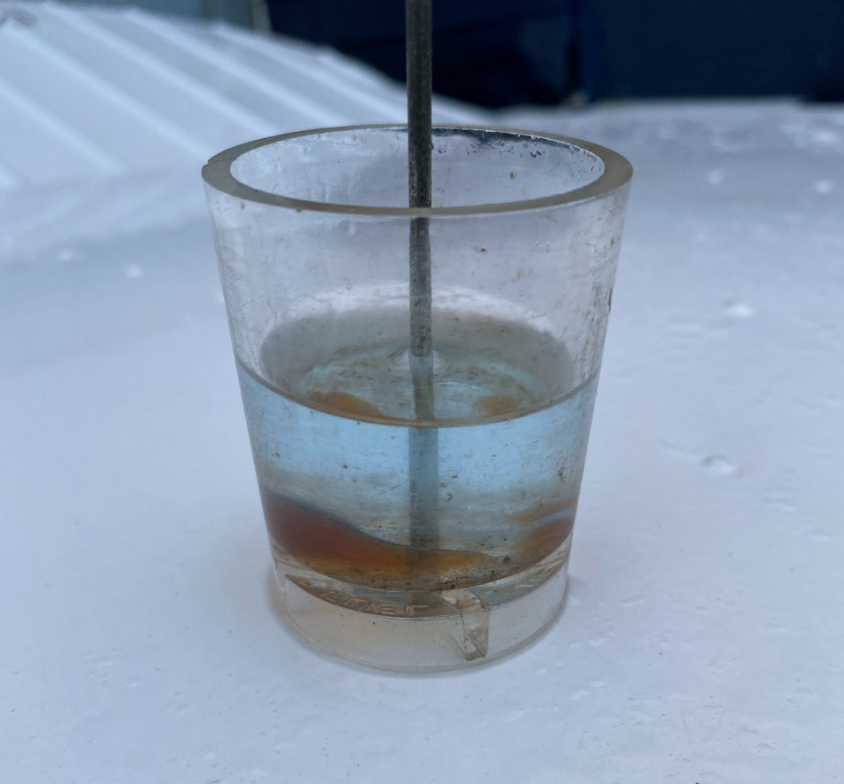

Visible sediment or cloudiness in your fuel samples.

-

Unusual engine performance or sluggish start-up.

-

Fluctuating fuel pressure.

-

Strong odor of microbial growth (yes, jet fuel bugs are a real thing).

Prevention: What Every King Air Pilot Should Check

-

Sample Before You Fuel – Always sump fuel from the source before it touches your tanks, especially in remote areas.

-

Inspect Your Fuel Samples – Look for discoloration, particles, or water separation.

-

Drain Your Sumps Frequently – Especially after the first fueling at a remote location.

-

Know Your Filters – Ensure aircraft fuel filters are in good condition and replaced per schedule.

-

Carry Your Own Gear – Portable fuel testers, water detection paste, and clean rags are worth their weight in gold.

-

Ask Questions – Don’t be afraid to ask the FBO or fuel provider about their filtration, tank maintenance, and fuel turnover rate.

What to Do if You Suspect Contamination

-

Do not fly until the fuel is confirmed safe.

-

Contact maintenance support immediately.

-

If possible, defuel and replace the load with confirmed clean fuel.

-

Document the incident, it can help you and others in the future.

Flying remote doesn’t have to mean taking unnecessary risks. A few extra minutes of diligence can prevent costly delays, in-flight emergencies, or engine damage.

If you have questions about King Air operations, upgrades, or want advice on handling a specific maintenance challenge, our team is here to help.

Email us at: info@kingairnation.com

Whether it’s fuel management, avionics upgrades, or a specific operational concern — we’d love to hear from you.