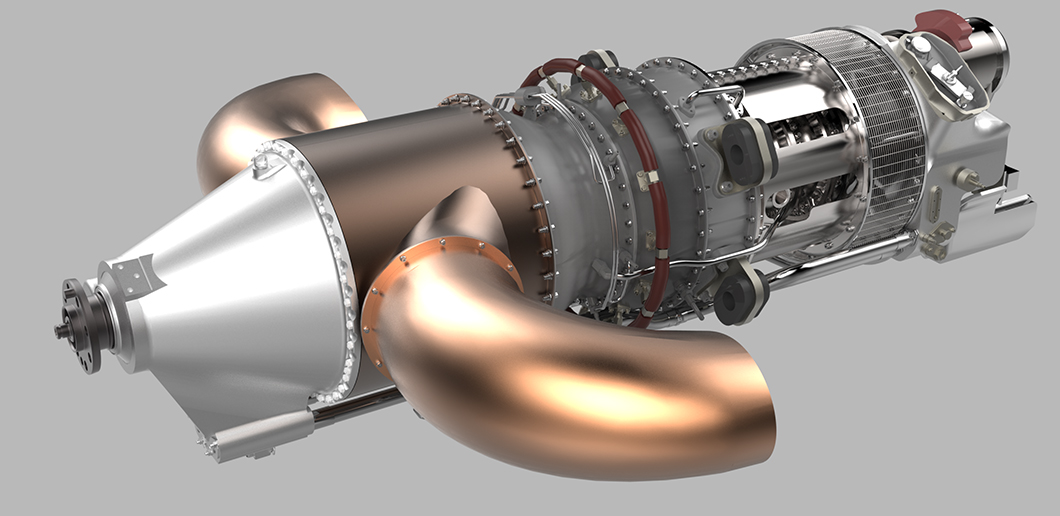

GE Aviation today unveiled its all-new turboprop engine, which has been selected by Textron Aviation to power its single engine turboprop (SETP). Textron Aviation and GE made the announcement aircraft-engine pairing today at the National Business Aviation Association’s annual tradeshow.

The 1,300 shaft horse power (SHP)-rated turboprop engine is the first entry in GE’s new family of turboprop engines aimed at Business and General Aviation aircraft in the 850-1,600 SHP range. According to GE, the engine features a 16:1 overall pressure ratio (OPR), enabling the engine to achieve up to 20% lower fuel burn and 10% higher cruise power compared to competitor offerings in the same size class with 4000-6000 hour time between overhauls (30% longer than current engines) and class-leading performance retention.

“Our single engine turboprop will combine the best of both clean-sheet aircraft and new engine designs. Selecting GE as our engine partner reflects the best fit for the mission of the aircraft and our commitment to reliably deliver best-in-class performance capabilities to our customers,” said Christi Tannahill, senior vice president, Turboprops and Interior Design at Textron Aviation. “By leveraging the newest technologies, we expect our SETP to outperform the competition in critical areas ranging from cabin size and acquisition cost to performance capability and fuel savings.”

Textron Aviation’s GE-powered SETP is expected to have a range of more than 1,500 nautical miles and speeds higher than 280 knots. Key features of GE’s new turboprop engine include:

- Ruggedized, modular architecture based on the T700/CT7 turboshaft for better performance at lower operating costs.

- All-titanium, 3D aero compressor design for light-weight and efficient power generation.

- Cooled turbine blades enabling higher thrust and fuel efficiency… leveraging the T700/CT7’s 100 million flight hours and more than 5 million flight hours in hot/harsh environments.

- Additive manufactured structural components for reduced weight, improved performance and durability.

- Integrated electronic propulsion control for optimized single-lever engine and propeller control.

GE expects to conduct the detailed design review (DDR) for the new turboprop in 2017 followed by the first full engine test in 2018.

“For the past five years, GE conducted design studies and actively researched the turboprop market to identify and integrate the best of our next-gen commercial and military technologies at the lowest cost and risk to our business aviation customers,” said Brad Mottier, Vice President and General Manager of GE Aviation’s Business & General Aviation and Integrated Systems division. “We’re honored to be selected by Textron Aviation for its newest turboprop program and look forward to growing aircraft applications in the coming years with our new turboprop engine.”

Development, testing and production of new turboprop engine will occur at GE Aviation’s new turboprop Center of Excellence in Europe, announced this past September. The new facility will represent an investment exceeding $400 million and ultimately support 500 – 1,000 new jobs.